#MECHANICAL AUTOCAD SOFTWARE#

By removing the need for physical materials and man-hours to build prototypes, AutoCAD makes it much easier for individual companies or startups with limited capital to create extremely complex and sophisticated mechanical drawings without investing any money.ĪutoCAD can significantly reduce costs after the initial purchase of the software by eliminating the need to buy or use physical materials in the preliminary design phase. The function of AutoCAD that can be mentioned is the reduction in the cost of the design process. It eliminates the need for conventional prototyping, which takes a significant amount of time and resources. Not only that, but AutoCAD can be used to correct errors in betas of existing machine equipment, so it can also act as correction software for the design that is input, making it incredibly dynamic. The software also aids in the interpretation of these designs, detecting flaws, errors, and inconsistencies that the mechanical engineer might overlook. This not only allows them to fine-tune their design before it goes into production, but it also saves them a lot of other resources. The software speeds up and simplifies the process by eliminating the need to draw new blueprints for each version of an idea and first drafts of designs. Simulation Models and Potential ScenariosĪutoCAD for mechanical engineering is used in the early stages of a design project to begin sketching ideas and analysing them to determine the best solution for a given problem. Users of AutoCAD software, also known as AutoCAD drafters, can benefit in a variety of ways by incorporating this technology into their jobs, including but not limited to the following: This article will take a step-by-step look at how Autocad positively impacts the mechanical industry.

As a result, the use of AutoCAD software plays an important role in mechanical engineers’ jobs. Especially if the initial design is particularly intricate and does not produce the desired result. While creating full-scale models of components, processes, products, machines, and so on is theoretically possible, it is unlikely to be feasible, either economically or physically. In this article, we will take a step-by-step look at how AutoCAD is dramatically improving the Mechanical Industry. These projects can range in scope from micro-components to motors/engines to large-scale machines and beyond. This can include the development of new machinery as well as the reconfiguration or enhancement of existing products and technologies. Mechanical engineers are responsible for providing effective and cost-effective solutions for the development of processes and products. As a result, these processes are given special attention and monitoring to ensure that these performance standards are met and profit targets are met or exceeded. In general, these mechanical systems are expected to produce precise and optimal results with minimal downtime or required maintenance. Mechanical systems are frequently used by businesses in a variety of industries, particularly the manufacturing sector, to achieve the desired outcome or end product. How AutoCAD Mechanical is Revolutionizing 3D Design

#MECHANICAL AUTOCAD FREE#

Students and educators can obtain free AutoCAD programmes through different learning platforms. The design is required to create models and prepare for component production, while the analysis aids in calculating stress levels, the influence of forces, and the influence of finite elements in a design.

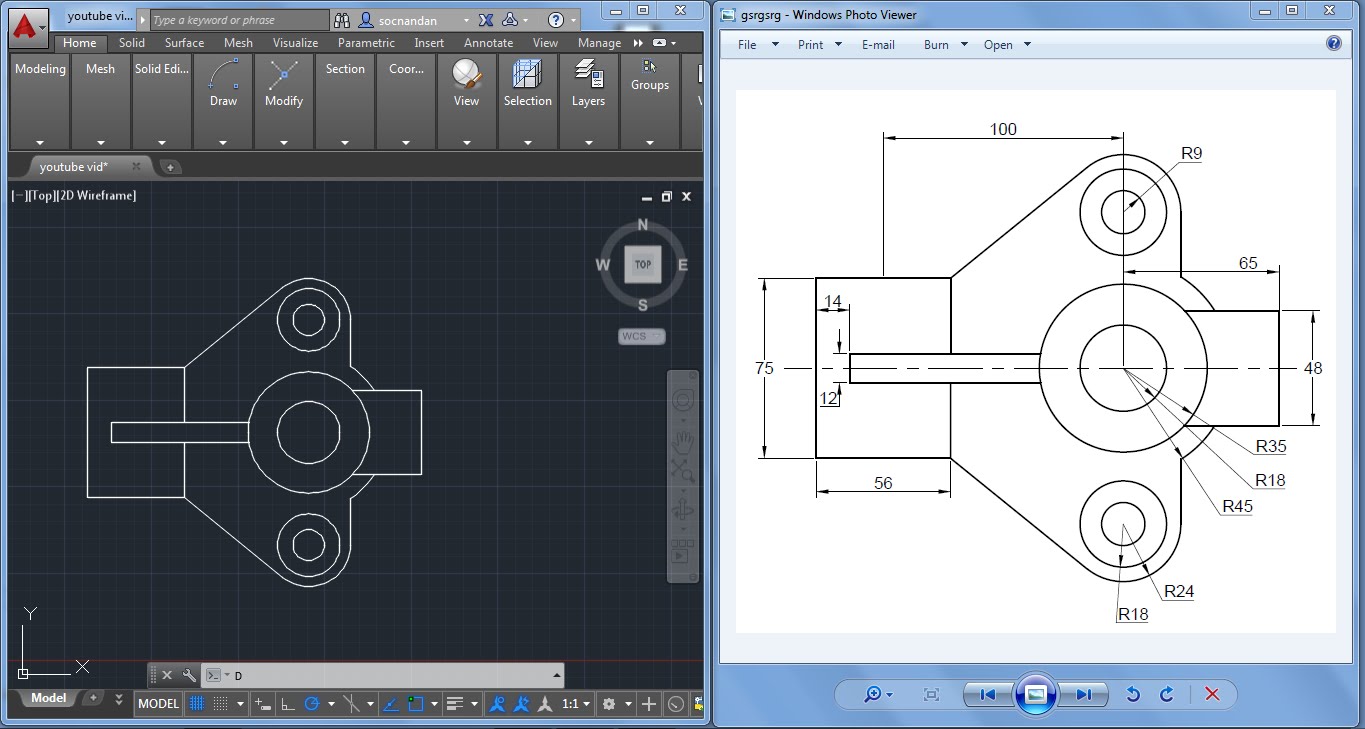

It comes with a set of tools for improving workflow and creating realistic maps, diagrams, structures, and schematics.ĬAD software combines design and analysis. CAD is an abbreviation for “Computer Aided Design.” AutoCAD is a two-dimensional and three-dimensional design software suite created by the Autodesk company.

0 kommentar(er)

0 kommentar(er)